In addition to working on my RoboMagellan robot, I decided to start a somewhat smaller and less ambitious project.

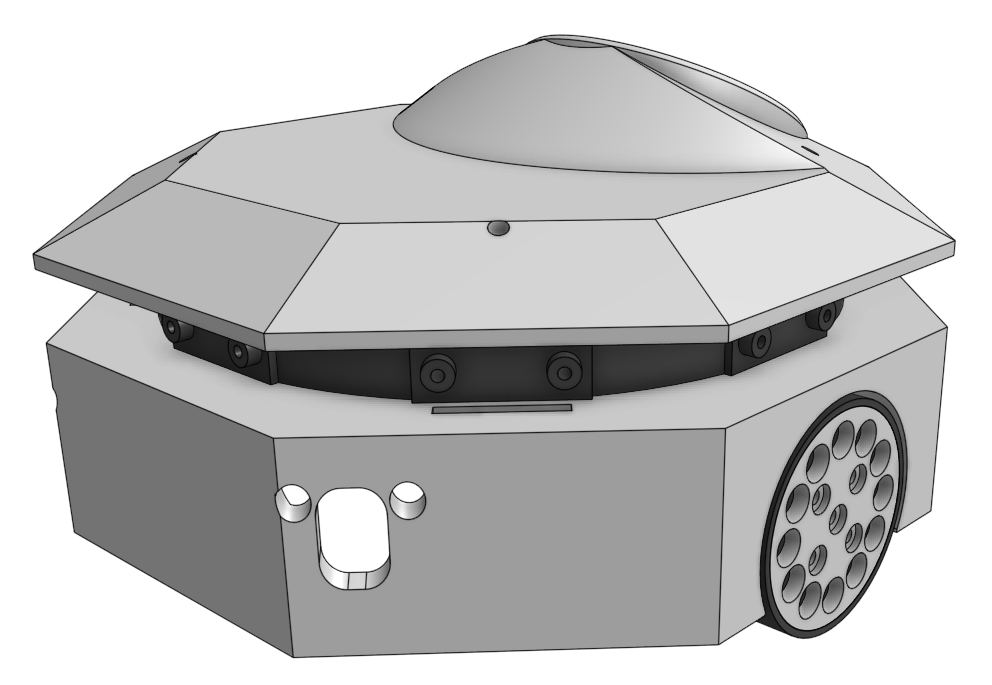

This is what I call a tabletop robot, because it is very small and will roll around the top of a table. One thing it should never do is fall off the table, and it has two down facing time-of-flight laser sensors in the front to help avoid that.

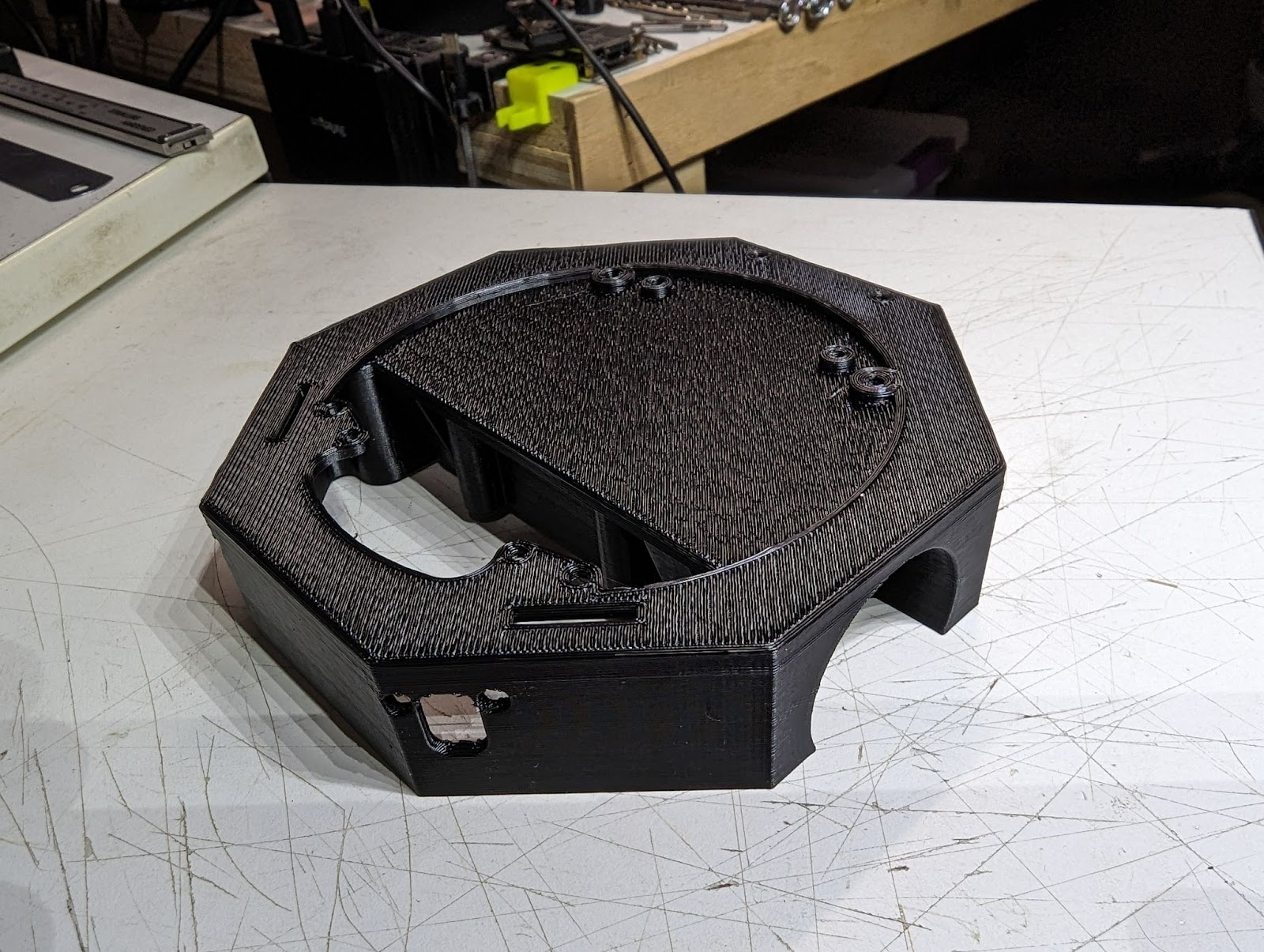

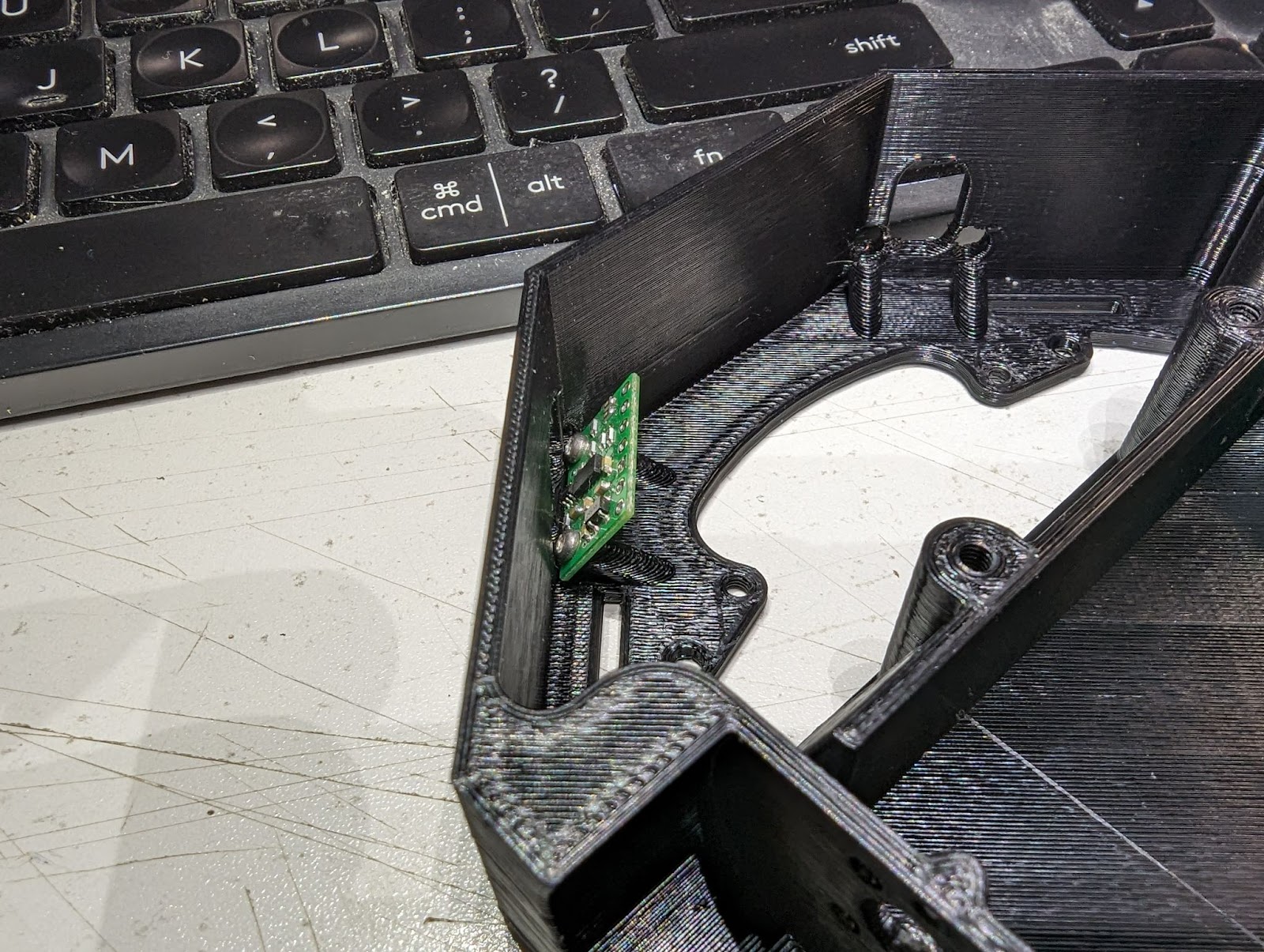

I’ve 3D printed the first version of the base of this robot (its a six hour print job).

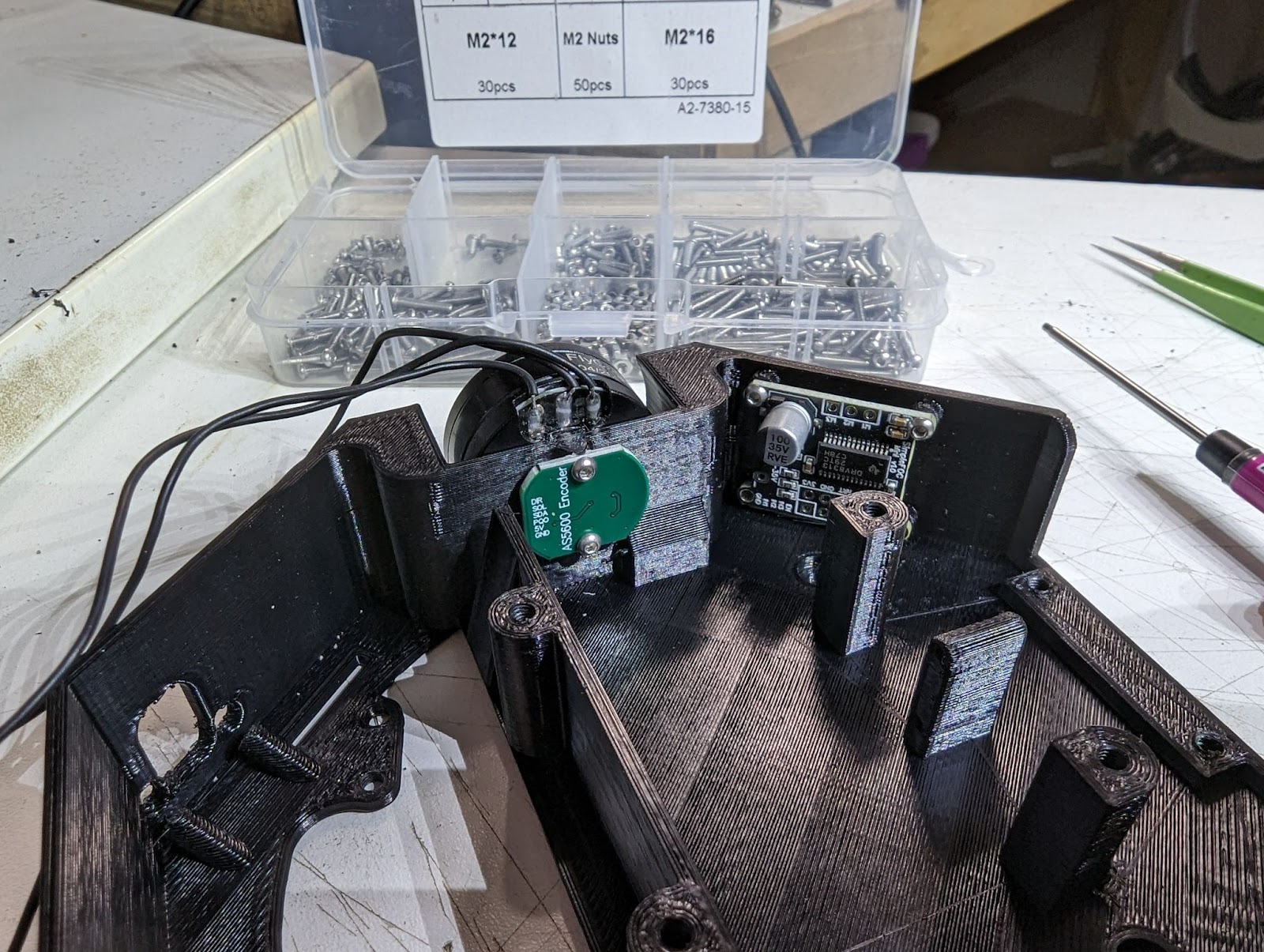

I always end up doing a few versions of complex parts, because you never get everything perfect the first time. In the image below, I’m test fitting a couple of the boards needed – the motor encoder, and the motor driver board, as well as the motor itself. One change I had to make to the CAD model already – I forgot to include a hole to run the motor wires though.

This robot is my first wheeled robot with brushless gimbal motors, and I’m looking forward to seeing how well they do.

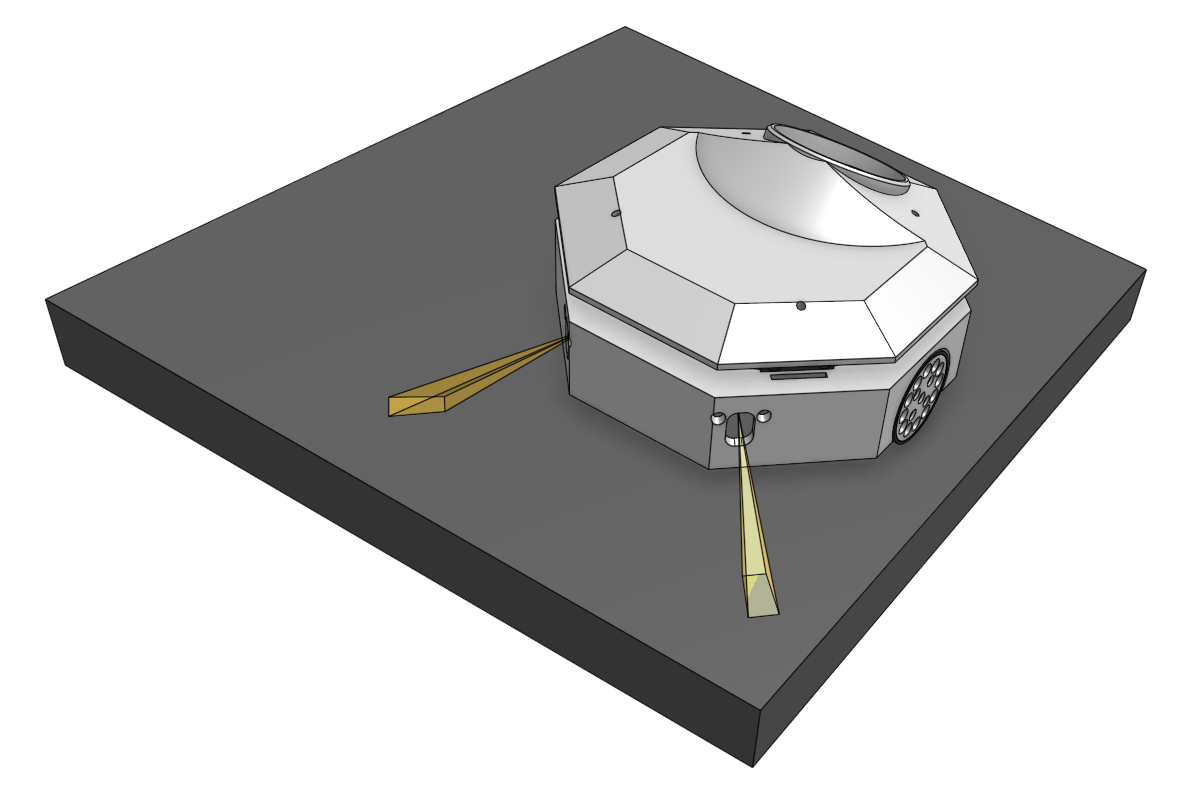

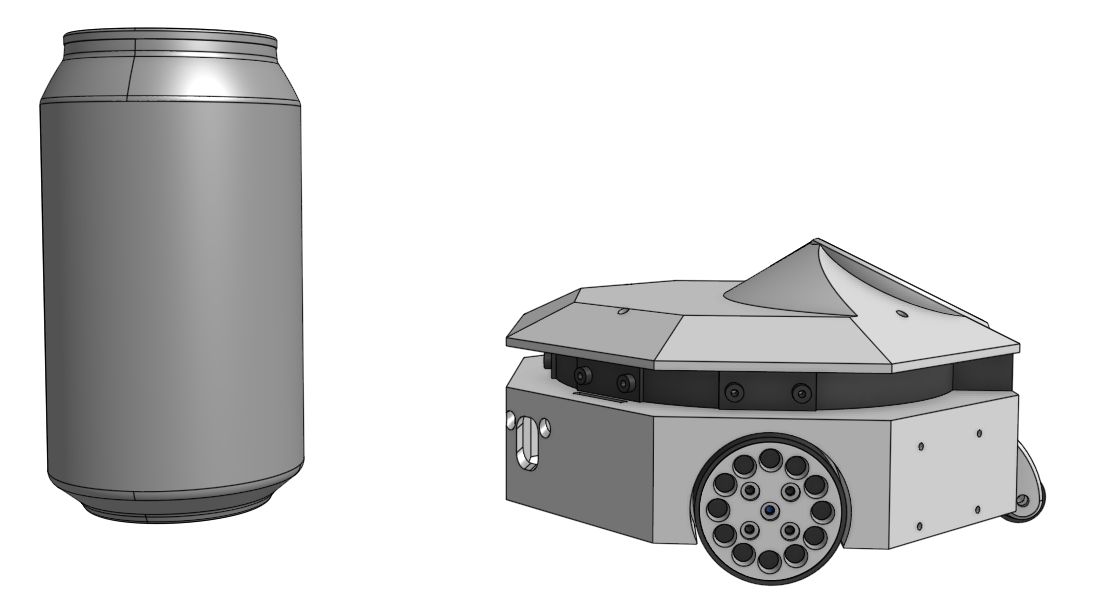

To give a sense of scale of this robot, here’s a render of it next to a normal 355ml (12 oz) pop or soda can:

Its going to be small and (hopefully) rather cute, but at the same time, very capable.

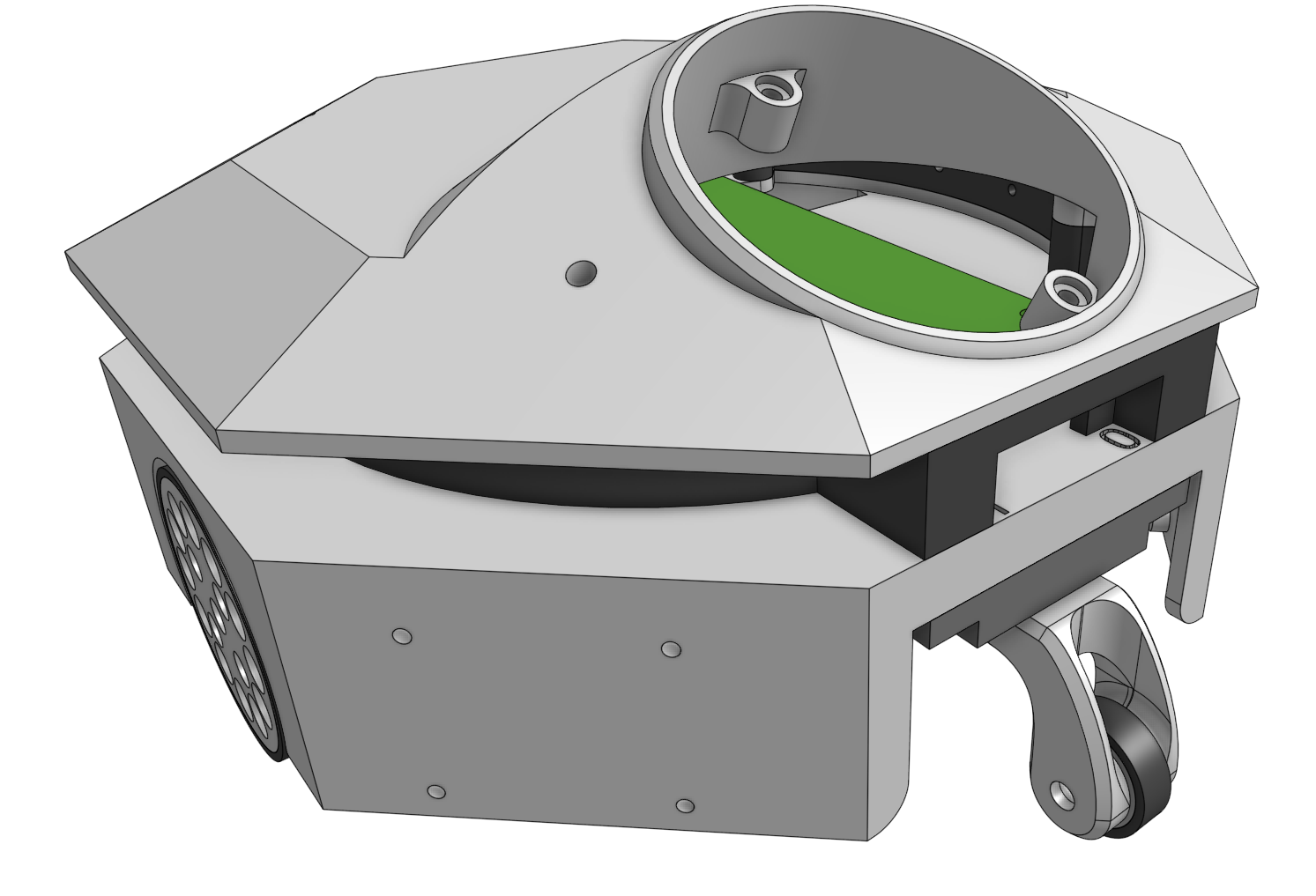

It will have a small round touch-screen display on top at the back, and you can see where that display screen will mount here:

That touch screen will be how I can interact with the robot, and how it can display status and information about what it is doing.

Here’s another picture, showing the chassis (upside down), with a laser range finder mounted.

The board, which will be a VL53L1X (from Pololu) points down at a thirty degree angle, and points out to the side at a forty-five degree angle. There will be a matching sensor on the other side. These range sensors will allow the robot to sense the edge of the table, either in front or if the robot is right next to the edge, from the side.

Inside the robot will be four different microcontrollers – all four of them will be Waveshare RP2040-Tiny boards. These are great little machines – they run MicroPython, and are small and very cheap (like $6 CAD each). The main RP2040 will be connected to the touch screen display, and it will talk to the others over a serial bus. The first device on the bus will be a sensor interface device, and it will gather all the sensor data (except the motor encoders – more about those later) and be able to give it to the bus master on request.

The other two RP2040’s will be motor drivers, for the brushless gimbal motors. Each motor gets a dedicated microcontroller. They will be responsible for controlling the motors and providing feedback to the bus master. They will implement a form of closed loop control by enforcing the requested speed using a PID loop with the encoder as the input sensor.

Overall, the robot is going to implement a subsumption-like set of behaviors, similar to what David Anderson uses on his smaller robots. All the code will be written in MicroPython.